Selection of material for the jacket

Our jackets have fabricated with genuine quality material that makes them durable and gives you utmost comfort. We manufacture our jackets and ensure the quality of the jackets is up to the latest standards. These jackets are perfect for all kinds of gatherings. Our leather jackets are must-have apparel to wear this winter season.

The Durability and Thickness of the material used in our Leather Jackets

We use genuine quality leather in the manufacturing of our leather jackets. The lambskin leather is used for the stitching of our jackets. We have a vast range of buffalo or cow skin leather jackets, and these jackets are even thicker and more durable. The GOAT skin leather is also very durable. Here at LJB, we have a team of experts who are professional in manufacturing all these kinds of leather jackets to provide the best quality to our customers.

Powerful Machines Used to Stitch for Ensuring the Durability of the Leather Jacket

Our jackets’ stitching is completed with powerful machines that make our leather jackets more durable and classy. According to the leather material, our team crafted jackets that are suitable to it; if the material is suitable to stitch in the machine, so we use machine or if handmade process suits more we prepare our jackets with handmade process. For a durable stitch on thick leather, we choose a special two-edged leather needle. The designers at LJB are perfect in their work.

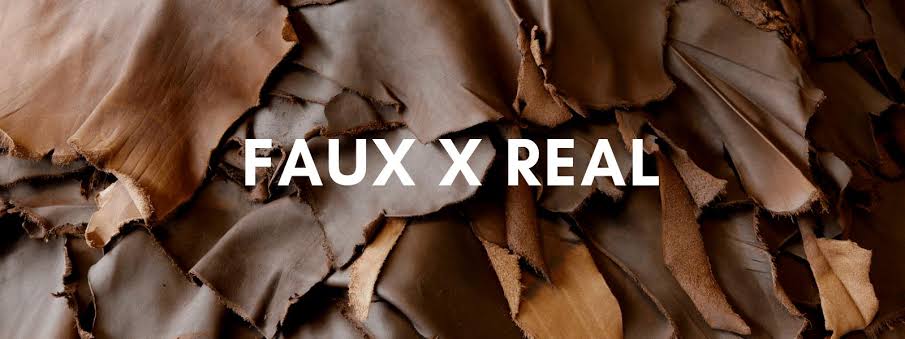

EACH SKIN IS DIFFERENT

We use high-quality genuine leather in manufacturing the jackets; various kinds of leather are used by our craftsmen, which is made up of the skin of the animals. This process ensures the best quality, avoiding traces of scars and imperfections, stretch marks, stains. Here at LJB, we select skins from the same tanning bath so that the color and properties of the leather are homogeneous.

Ensure the Manufacturing According to the Standards

The design of a leather jacket requires a good knowledge of specific crafting techniques to ensure accurate and quality work. LJB ensures that all leather jackets must have perfectly fabricated and should have a unique texture. These manufacturing standards ensure the durability of jackets.